As with all of our ciders, from pressing to the finished product, we insist on full control. We do all of our own bottling on the farm and have invested heavily over the last few years in our bottling facilities. This included the commissioning of our state of the art bottling line in 2007, which has made life alot easier, in fact we can now bottle the same number of bottles in one day as we previously did in four or five days.

As with all of our ciders, from pressing to the finished product, we insist on full control. We do all of our own bottling on the farm and have invested heavily over the last few years in our bottling facilities. This included the commissioning of our state of the art bottling line in 2007, which has made life alot easier, in fact we can now bottle the same number of bottles in one day as we previously did in four or five days.How the bottling line works ....

The process is mostly automated and starts with the empty bottles being hand fed onto the loading conveyor. The bottles are then conveyed into

The process is mostly automated and starts with the empty bottles being hand fed onto the loading conveyor. The bottles are then conveyed intothe filling machine where they are quickly rinsed before being filled and capped at speeds of around 1600 bph (bottles per hour).

Once the bottles are filled, the cider goes through our tunnel pasteuriser which gently heats the cider up to around 64 degrees celcius for 20 minutes to kill any remaining yeast cells in the cider and make sure the product is totally stable for selling.

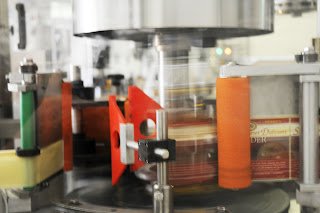

Once pasterurised, the bottles come out of the tunnel cooled and any excess water on the bottles is blasted off by our twin air knifes. The bottles are then ready for labelling. The filled, capped, pasteurised and labelled bottles are then shrink-wrapped and palletted, ready for storage, and eventually drinking!

Although the bottling line has made life alot easier on the farm, the line still requires a high level of human contact, as even the best technology has a habit of being uncooperative at times, and things can get very stressful when bottles start flying of the end, unlabelled and half filled!

Now, on a different note, we have now learnt that bees come with differing degrees of aggression and that simply waiting for a swarm to arrive can result in some pretty nasty bees! So plan two is to find someone reputable to buy a nucleus of friendly bees from. Recommendations welcome!

(Bee at work)

(Bee at work)